Digital Tools Revolutionize Quality Control Inspection Efficiency

Digital transformation in quality control inspection has revolutionized industries by replacing manu…….

In the modern global economy, where products and services traverse borders with ease, ensuring quality has become a paramount concern for businesses and consumers alike. Quality Control Inspection (QCI) stands as a critical process, acting as a vigilant guardian against subpar offerings, thus safeguarding consumer rights and fostering market trust. This article aims to embark on an in-depth journey through the world of QCI, exploring its multifaceted aspects, global impact, and the transformative potential it holds for various industries.

Definition: Quality Control Inspection is a systematic process employed by manufacturers, service providers, and regulatory bodies to assess and ensure the quality of products, services, or processes. It involves a series of rigorous tests, examinations, and evaluations designed to identify defects, deviations from standards, and potential risks.

At its core, QCI encompasses several key components:

Standardization: Establishing clear, measurable quality standards and specifications against which performance can be evaluated. These standards ensure consistency and provide a benchmark for comparison.

Monitoring and Testing: Implementing processes to monitor the production or service delivery pipeline continuously. This includes various testing methods like functional testing, performance testing, and safety assessments to identify deviations from the defined standards.

Comparison and Analysis: Comparing the actual product/service output with the desired specifications. Statistical analysis is often employed to detect patterns, trends, and potential sources of variation or non-conformance.

Correction and Improvement: Identifying and rectifying any deviations or defects found during inspection. This step involves implementing corrective actions to address the root causes and prevent recurrence. Continuous improvement processes, such as Six Sigma and Lean Manufacturing, are often integrated into QCI frameworks.

Historically, quality control has evolved from simple inspection methods in the early 20th century to sophisticated, data-driven systems today. The advent of statistical process control (SPC) during World War II marked a significant shift, enabling manufacturers to monitor and improve their processes more effectively. Over time, QCI embraced technological advancements like automation, digital imaging, and advanced analytics, enhancing its efficiency and accuracy.

Quality Control Inspection is not confined to any specific region; it is a global phenomenon that has left an indelible mark on international trade and industry. Its influence cuts across various sectors, from automotive and electronics to healthcare and food production.

North America: Known for its stringent quality standards, particularly in the automotive and aerospace industries, North American countries like the United States and Canada have long prioritized QCI. The region’s emphasis on continuous improvement, driven by iconic companies like Ford and General Motors, has set a high bar for global quality control practices.

Europe: With a robust regulatory framework, Europe leads in consumer protection and product safety standards. Countries like Germany and the United Kingdom are renowned for their rigorous QCI procedures in manufacturing, especially in the automotive and pharmaceutical sectors. The European Union’s (EU) stringent compliance requirements have also influenced global quality control trends.

Asia Pacific: This region, led by China and Japan, has emerged as a manufacturing powerhouse. Asian countries have embraced QCI to ensure product quality and gain international market access. The emphasis on lean manufacturing and just-in-time inventory management has driven the adoption of advanced QCI techniques in these nations.

Middle East and Africa: While these regions may face unique challenges, they are also witnessing significant growth in QCI. The Middle East’s focus on infrastructure development and the African continent’s growing industrial base have led to increased investment in quality control infrastructure.

Digital Transformation: The integration of digital technologies into QCI processes is a prominent trend. Digital imaging, computer-aided inspection (CAI), and automated test equipment enhance accuracy and speed. Artificial intelligence (AI) and machine learning algorithms promise to revolutionize QCI by enabling predictive analytics and autonomous quality monitoring.

Supply Chain Visibility: With complex global supply chains, ensuring product quality across multiple stages has become a challenge. Advanced tracking systems, IoT devices, and real-time data analytics are being employed to increase visibility and control, allowing for more effective QCI strategies.

Sustainability and Eco-Friendly Practices: Environmental considerations have entered the realm of QCI. Many industries are adopting sustainable quality control practices, focusing on eco-friendly materials, processes, and waste reduction. This trend is particularly evident in sectors like textiles, packaging, and electronics.

The economic implications of Quality Control Inspection are profound, impacting market dynamics, consumer behavior, and business strategies worldwide.

In today’s globalized marketplace, quality is a critical differentiator for businesses. High-quality products and services command premium prices and foster customer loyalty. QCI plays a pivotal role in helping companies meet or exceed consumer expectations, thus gaining a competitive edge. A study by the Global Business Council revealed that 86% of consumers are willing to pay more for superior quality products, underscoring the economic impact of effective QCI.

Implementing robust QCI systems involves initial investment in training, equipment, and infrastructure. However, long-term benefits include reduced waste, lower rework costs, and improved product/service reliability. A 2020 report by McKinsey suggested that companies with strong quality management practices can achieve significant cost savings, often exceeding the implementation costs within a few years.

Stringent quality control standards are often associated with specific countries or regions, creating opportunities and challenges for international traders. Countries like Japan and Germany have built reputations for high-quality products, which has contributed to their global market dominance. Conversely, nations looking to gain a competitive edge in specific sectors may need to invest heavily in QCI infrastructure to meet international standards.

Technological innovation has been a catalyst for transformation in Quality Control Inspection, enabling more efficient, precise, and data-driven processes.

Automation has revolutionized QCI by increasing speed, consistency, and accuracy. Automated testing equipment can perform repetitive tasks with minimal human intervention, reducing the risk of errors. Robotic process automation (RPA) is being used to automate inspection routines, freeing up human resources for more complex quality assurance duties.

CAI systems use software to guide inspectors through complex procedures and analyze results. These tools enhance accuracy by providing real-time feedback and reducing the subjectivity often associated with manual inspections. CAI is widely used in industries like aerospace, automotive, and electronics for precise measurements and detailed documentation.

Advanced digital imaging techniques, including high-resolution cameras and 3D scanning technologies, enable non-destructive testing (NDT). This method visually inspects products without causing damage, making it ideal for delicate or valuable items. 3D scanning also aids in creating digital prototypes, facilitating faster design iterations and quality control.

The marriage of AI and QCI promises to bring about a new era of intelligent inspection. AI algorithms can analyze vast datasets, identify complex patterns, and make predictions. For example, machine learning models can forecast product defects based on historical data, enabling proactive quality control measures. Natural Language Processing (NLP) is also being utilized to interpret and categorize inspection findings more efficiently.

Governments and international bodies play a crucial role in shaping the landscape of Quality Control Inspection through policies, regulations, and standards.

ISO, with its various standards, provides a global framework for quality management systems. ISO 9001 is the most renowned standard, offering guidelines for establishing, implementing, maintaining, and continually improving quality management systems. Many countries have incorporated ISO standards into their national regulatory frameworks, making them mandatory for businesses.

Different regions have distinct regulatory bodies and standards governing QCI. For instance, in the European Union, the General Data Protection Regulation (GDPR) ensures data privacy, while REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulates chemical safety. The United States has agencies like the FDA (Food and Drug Administration) for food safety and the DOT (Department of Transportation) for transport-related products.

Certain industries have their own stringent standards and regulations. For example, the automotive sector follows ISO/TS 16949, which is a quality management standard specifically tailored to automotive production. The aerospace industry relies on AS9100, a quality system standard based on ISO 9001 but with added requirements for safety and reliability.

Despite its numerous benefits, Quality Control Inspection is not without challenges and criticisms that require thoughtful strategies to address.

Cost and Resource Allocation: Implementing robust QCI systems can be expensive, particularly for small and medium-sized enterprises (SMEs). Balancing investment in quality control with other operational costs is a constant challenge.

Skilled Workforce Shortage: The demand for skilled inspectors and quality assurance professionals often outstrips the available talent pool. Training programs and industry collaborations are needed to bridge this gap.

Keeping Up with Technological Change: As technology advances, so do expectations for QCI capabilities. Staying abreast of new technologies and integrating them effectively into existing systems can be daunting.

Global Harmonization: The absence of a unified global quality control framework creates challenges in international trade. Companies must navigate varying standards and regulations across different markets.

Overemphasis on Testing: Critics argue that QCI often becomes overly focused on testing, neglecting other essential aspects like process improvement and customer satisfaction. Balancing these elements through a holistic quality management approach is crucial.

Data Privacy Concerns: With the increasing use of digital technologies, data privacy has become a concern. Implementing stringent data protection measures and ensuring transparency in data handling can address these issues.

Standardization Gaps: Differences in international standards can create confusion and compatibility issues. Standardizing protocols and promoting collaboration among standard-setting bodies can help overcome these challenges.

Toyota Motor Corporation is renowned for its lean manufacturing philosophy, which has significantly influenced global quality control practices. The company’s focus on eliminating waste, continuous improvement, and just-in-time inventory management has resulted in exceptional product quality. Toyota’s QCI system involves rigorous inspection at every production stage, empowering employees to identify and rectify issues promptly. This approach has contributed to Toyota’s consistent delivery of high-quality vehicles worldwide.

The United States Food and Drug Administration (FDA) conducts regular inspections of food manufacturing facilities to ensure compliance with safety standards. These inspections cover various aspects, including facility sanitation, employee training, and record-keeping. The FDA’s strict enforcement of quality control measures has played a vital role in safeguarding public health and maintaining consumer trust in the food industry.

Airbus, a global aerospace manufacturer, employs sophisticated QCI methods to ensure the safety and reliability of its aircraft. Their system includes comprehensive testing, simulation, and data analysis. Airbus’s digital inspection tools enable real-time monitoring and rapid identification of potential issues. This case study highlights the successful integration of advanced technologies in aviation quality control.

The future landscape of Quality Control Inspection is brimming with opportunities for growth, innovation, and strategic development.

Emerging Markets: With the rise of manufacturing hubs in Asia, Africa, and South America, there is a growing demand for advanced QCI systems to meet international quality standards.

Healthcare and Pharmaceuticals: The healthcare industry’s focus on patient safety and product efficacy drives the need for stringent QCI practices, particularly in drug development and medical device manufacturing.

Smart Factories: The concept of Industry 4.0, featuring smart factories equipped with IoT devices and AI, will significantly impact QCI. Real-time data analysis and predictive maintenance will become more prevalent.

Blockchain for Supply Chain Transparency: Blockchain technology offers a transparent and secure way to track products throughout the supply chain. This can enhance product traceability and enable more effective QCI strategies.

Quantum Computing Applications: While still in its infancy, quantum computing has the potential to revolutionize data analysis, enabling faster and more complex quality control algorithms.

Augmented Reality (AR) Inspections: AR technology can overlay digital information on physical products during inspection, providing real-time guidance and enhancing accuracy.

Data Analytics and AI Integration: Companies should invest in developing data analytics capabilities to gain insights from QCI data. AI-driven quality control systems will become more prevalent, enabling predictive maintenance and automated defect detection.

Global Standardization Efforts: Collaborating with international organizations to harmonize standards can facilitate global trade and reduce costs for businesses.

Continuous Learning Organizations: Adopting a culture of continuous learning and improvement is essential to staying ahead in the rapidly evolving quality control landscape.

In a world where products and services are interconnected globally, Quality Control Inspection stands as a cornerstone of modern business and consumer protection. Its role in ensuring product quality, safety, and reliability cannot be overstated. This article has provided an in-depth exploration of QCI, highlighting its historical development, global impact, economic significance, technological advancements, regulatory frameworks, and challenges.

Through case studies and an analysis of future trends, it is evident that QCI will continue to evolve, driven by digital transformation, sustainability concerns, and the relentless pursuit of excellence. As businesses navigate an increasingly complex and interconnected world, effective quality control practices will remain a competitive advantage, fostering customer trust and driving success in diverse industries.

1. What is the primary purpose of Quality Control Inspection?

2. How does QCI benefit businesses?

3. What are some common quality control methods used today?

4. Can you explain the role of AI in modern QCI systems?

5. How does global standardization impact quality control?

Digital transformation in quality control inspection has revolutionized industries by replacing manu…….

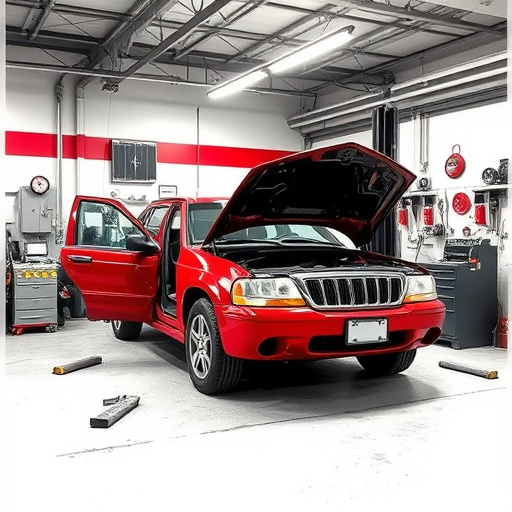

Quality control inspection is a vital process for auto repair and restoration industries, ensuring e…….

Safety verification is essential in quality control inspections for high-risk industries like automo…….

Quality control inspections in automotive repair and bodywork services utilize visual exams, pressur…….

OEM repair standards are crucial for vehicle safety and quality. Quality control inspection is a key…….

Quality control inspections rigorously test airbags, sensors, and Advanced Driver-Assistance Systems…….

Collision repair quality control inspections involve comprehensive assessments of vehicle components…….

Quality control inspection is vital for auto repair shops, ensuring customer satisfaction by identif…….

Quality control inspections are vital for accurate insurance claim processing in auto repairs, ensur…….