Certified technicians conduct meticulous quality control inspections to ensure vehicle repairs meet highest standards. They identify and rectify minor imperfections like car scratches and fender bends, ensuring flawless finishes that match original factory specs. This rigorous process builds customer trust, enhances industry reputation for excellence in services like dent repair and paintwork.

In today’s manufacturing landscape, certified technicians play a pivotal role in ensuring product excellence through meticulous quality control (QC) inspections. This article delves into the essential duties and responsibilities of these specialists, highlighting their crucial contribution to the final QC process. Understanding their key tasks empowers us to appreciate how their work directly influences the overall quality and reliability of products. Let’s explore why their role is indispensable in modern industry.

- Understanding Quality Control Inspection Role

- Responsibilities of Certified Technicians

- Ensuring Final Product Excellence through Inspections

Understanding Quality Control Inspection Role

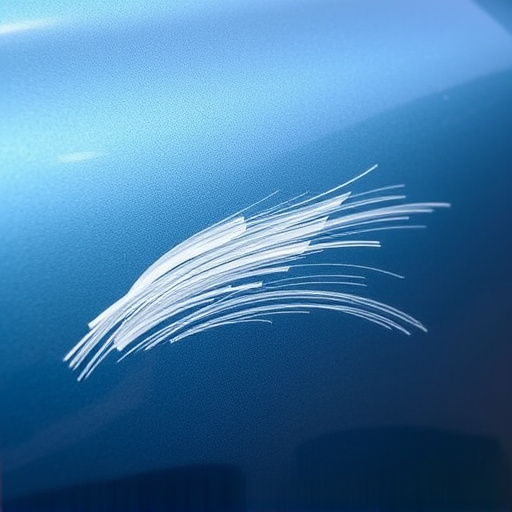

Quality control inspection is a critical process that ensures every vehicle leaving the workshop meets the highest standards. Certified technicians, armed with meticulous attention to detail and specialized knowledge, play a pivotal role in this procedure. Their primary responsibility is to meticulously examine every aspect of the repair work, including intricate details often overlooked by untrained eyes. This includes checking for any imperfections, such as unsightly car scratches or faint fender bends, which could indicate inadequate repairs during the initial damage assessment phase.

These technicians are not just inspectors; they are the final safeguard against subpar work. For instance, in cases of vehicle dent repair, their scrutiny ensures that dents are not only removed but also that the paint job is flawless and seamless, matching the original factory finish. By upholding these rigorous standards, certified technicians contribute to building customer trust and ensuring satisfaction with repairs like car scratch repair and fender repair services.

Responsibilities of Certified Technicians

Certified Technicians play a pivotal role in ensuring the highest standards of quality across various industries, particularly in vehicle restoration and paintless dent repair. Their primary responsibility is to conduct meticulous quality control inspections, serving as the final safeguard before a product or service is deemed ready for customer delivery. These inspections encompass a comprehensive evaluation of every detail, from identifying subtle car scratch repairs to assessing the overall aesthetic appeal of a restored vehicle.

In the realm of vehicle restoration and paintless dent repair, Certified Technicians are tasked with applying their expertise to detect even the most minute imperfections. They meticulously examine surfaces, ensuring color consistency, seamless panel gaps, and the absence of any visible dents or scratches. By upholding rigorous quality standards, these technicians contribute to client satisfaction and ensure that restored vehicles meet or exceed initial factory specifications, fostering a reputation for excellence in the industry.

Ensuring Final Product Excellence through Inspections

In the realm of precision craftsmanship, certified technicians play a pivotal role in ensuring final product excellence through meticulous quality control inspections. These inspections serve as the crucible where every detail is scrutinized, upholding the highest standards across various industries, notably automotive body work, car damage repair, and vehicle collision repair. By implementing rigorous checks, they identify even the subtlest imperfections, preventing subpar outcomes that could mar the overall quality.

Through their expert eyes, certified technicians navigate complex landscapes of vehicle components, identifying potential issues that may have gone unnoticed otherwise. This meticulous process not only guarantees the safety and reliability of repaired vehicles but also enhances customer satisfaction. By prioritizing comprehensive quality control inspections, these professionals ensure that each vehicle leaves the workshop in immaculate condition, ready to hit the road with confidence.

Certified technicians play a pivotal role in ensuring final product excellence through meticulous quality control inspections. By understanding their responsibilities and adhering to stringent standards, these professionals safeguard consumer satisfaction and maintain the reputation of manufacturing and production companies alike. Quality control inspections remain an indispensable process, driving continuous improvement and upholding the highest levels of product quality in today’s competitive market.