Digital transformation in quality control inspection has revolutionized industries by replacing manual processes with efficient software and hardware solutions. Advanced tools like high-resolution cameras and imaging software improve precision, data analytics provide valuable insights, and real-time feedback ensures consistent excellence. This is particularly beneficial in manufacturing and automotive services, enabling more accurate defect detection and fostering uniform quality standards across different locations. Automation streamlines operations, reduces time and resources, and allows QC teams to focus on intricate tasks, enhancing productivity and product quality.

In today’s digital era, quality control (QC) inspection has evolved dramatically with advanced tools revolutionizing manufacturing and production processes. This article delves into how digital technologies are enhancing accuracy in QC, marking a new era of precision and efficiency. We explore visual inspection technologies that offer microscopic detail, and automation’s role in streamlining complex tasks. By embracing these innovations, industries can ensure superior product quality, reduce errors, and gain a competitive edge.

- Digital Tools: A New Era for Quality Control

- Enhancing Precision: Visual Inspection Technologies

- Streamlining Processes: Automation's Role in QC

Digital Tools: A New Era for Quality Control

The advent of digital tools has ushered in a new era for quality control inspection, revolutionizing how industries ensure product excellence. Traditional methods, often manual and time-consuming, have given way to sophisticated software and hardware solutions that enhance precision and efficiency. These cutting-edge tools are transforming various sectors, from manufacturing to automotive services, including car paint repair and tire services.

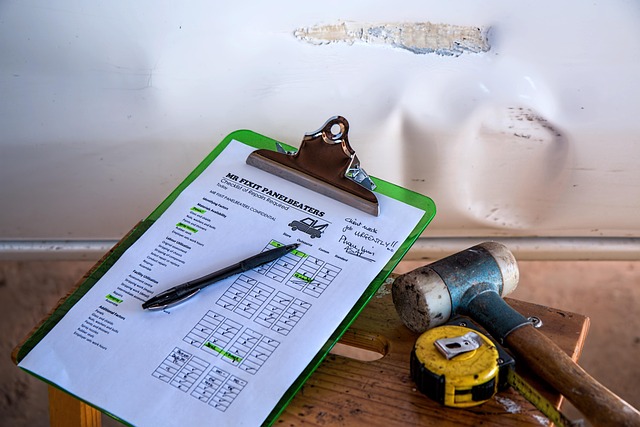

Digital technologies offer a range of benefits, such as improved visibility, data analytics, and real-time feedback. For instance, high-resolution cameras and sensors can capture intricate details during the quality control process, allowing for more accurate defect detection in car bodywork. Advanced imaging software enables precise measurements and comparisons, ensuring that every component meets stringent standards. Moreover, digital platforms facilitate seamless communication between inspectors, fostering a culture of consistent quality across different locations.

Enhancing Precision: Visual Inspection Technologies

Digital tools have revolutionized quality control inspection processes, significantly enhancing precision and efficiency. Among these technologies, visual inspection tools stand out for their ability to capture intricate details with unparalleled accuracy. High-resolution cameras, coupled with advanced image processing algorithms, enable inspectors to detect even the subtlest defects in materials and finishes, be it in manufacturing or car bodywork services.

These digital solutions offer a clearer and more detailed view of the product under inspection, allowing for more consistent and repeatable results. For auto body services, this means that every dent, scratch, or misalignment can be precisely documented and addressed, ensuring a higher standard of repair across the board. The use of these technologies not only improves overall quality control but also reduces the time required for manual inspection, making car paint services more efficient and cost-effective.

Streamlining Processes: Automation's Role in QC

In today’s digital era, automation is revolutionizing quality control (QC) inspection processes across various industries, especially in sectors like automotive manufacturing. Streamlining operations through advanced digital tools has become a game-changer for maintaining high standards of precision and efficiency. For instance, automated systems can swiftly scan and analyze complex components or entire vehicle bodywork, identifying defects or inconsistencies that might escape human detection. This level of automation ensures consistent and thorough inspections, significantly reducing the time and resources required compared to manual methods.

By integrating digital solutions, QC teams can focus on more intricate tasks while leaving repetitive, time-consuming work to machines. In auto painting, for example, robotic systems can accurately apply paint coats with impeccable consistency, minimizing human error and ensuring a flawless finish. This automation not only boosts productivity but also enhances overall product quality, making it an invaluable asset in any modern QC inspection regimen.

Digital tools are transforming quality control inspection, enhancing accuracy and efficiency. Visual inspection technologies and automation play a crucial role in this evolution, allowing for more precise and streamlined processes. By adopting these innovative solutions, companies can ensure superior product quality, reduce human error, and gain a competitive edge in their respective industries. This new era of digital quality control promises to revolutionize manufacturing and production standards globally.