Quality control inspections in automotive repair, especially classic car restoration, go beyond visual standards to assess environmental compliance. Inspectors evaluate waste management, air and water quality, adherence to local laws, and use of eco-friendly equipment, promoting sustainable practices that minimize the industry's environmental impact while maintaining quality repairs. In an environmentally conscious world, these inspections are vital for promoting sustainability in car bodywork services, preserving the planet for future generations.

In today’s eco-conscious world, environmental compliance is an integral part of any robust quality control process. This article delves into the significance of checking environmental standards during inspections, offering a comprehensive guide for businesses. We explore key areas where non-compliance may arise and highlight how rigorous checks can drive sustainability. By understanding these aspects, organizations can ensure their operations meet ecological expectations, all while maintaining stringent quality control measures.

- Understanding Environmental Compliance in Quality Control

- Key Areas Checked During Inspections

- Ensuring Sustainability Through Rigorous Checks

Understanding Environmental Compliance in Quality Control

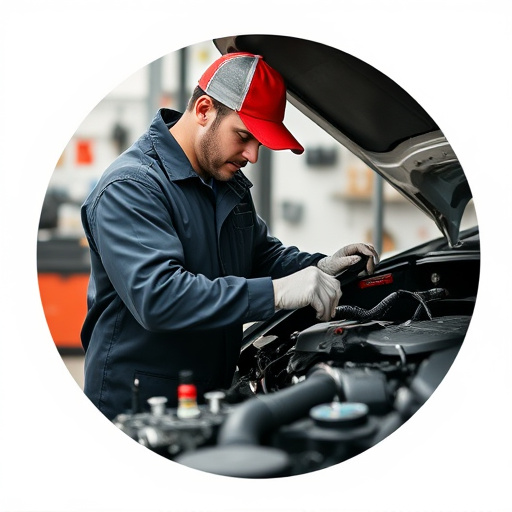

Environmental compliance is an integral part of any quality control inspection, especially in industries like automotive repair. A quality control inspector isn’t just checking for perfect panel alignment or paint precision in a dent repair or car body repair; they’re also assessing whether the process and facilities adhere to environmental regulations. This includes safe disposal methods for hazardous materials commonly found in auto repair shops, such as solvents and old batteries.

During a quality control inspection, the focus shifts beyond visual perfection to encompass sustainability and safety. It involves scrutinizing procedures related to waste management, air quality, water conservation, and adherence to local environmental laws. Ensuring these aspects not only meets legal standards but also contributes to a greener auto repair industry, promoting eco-friendly practices in dent repair and car body repair processes.

Key Areas Checked During Inspections

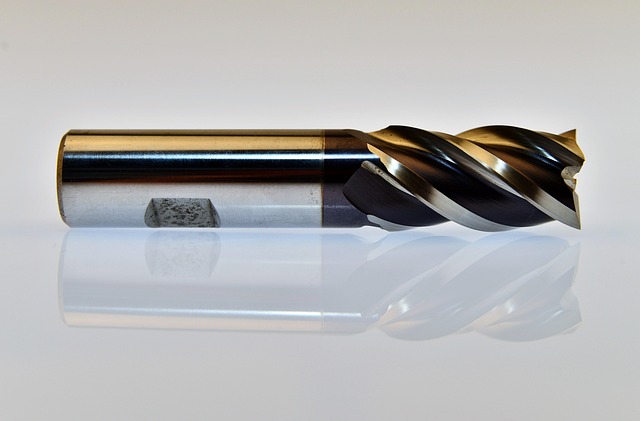

During a quality control inspection, several key areas are meticulously scrutinized to ensure adherence to environmental standards. These inspections go beyond surface-level checks, delving into processes and procedures that can impact the environment, especially in industries like classic car restoration and luxury vehicle repair. One critical aspect is waste management, where inspectors verify proper disposal methods for hazardous materials commonly found in automotive parts and fluids. This includes checking for appropriate containment and labeling of waste to prevent ecological contamination.

Furthermore, energy consumption and emissions are under the microscope. In the case of classic car restoration and other specialized vehicle services, this might involve assessing the efficiency of heating, ventilation, and air conditioning systems, as well as examining equipment for eco-friendly alternatives to traditional, more polluting practices. The goal is to identify areas where improvements can be made to minimize environmental impact, ensuring that quality control extends beyond mere cosmetic repairs into a comprehensive commitment to sustainability.

Ensuring Sustainability Through Rigorous Checks

In today’s world, where environmental consciousness is paramount, quality control inspections play a pivotal role in ensuring sustainability. Rigorous checks during these inspections go beyond mere adherence to regulations; they are a commitment to preserving our planet for future generations. Every aspect of a car bodywork service or collision center operation must be scrutinized, from waste management practices to the use of eco-friendly materials and equipment. This comprehensive approach not only minimizes the environmental impact but also fosters a culture of responsibility within the car repair shop.

By integrating sustainable practices into quality control, these facilities contribute to a greener landscape. From using recycled materials in repairs to implementing efficient energy systems, every step counts. Moreover, regular compliance checks help identify areas for improvement, enabling car repair shops to stay ahead of environmental regulations and continuously enhance their ecological footprint. This commitment not only benefits the environment but also strengthens the reputation of these businesses as responsible stewards of our planet.

Environmental compliance is an integral part of any successful quality control process. By thoroughly checking key areas during inspections, organizations can ensure they meet sustainability standards and regulatory requirements. This rigorous approach not only protects the environment but also strengthens a company’s commitment to responsible practices, fostering a greener future for all. Incorporating these checks into quality control inspection routines is a vital step towards a more sustainable and compliant business model.