Proper lighting is crucial for quality control inspection across various industries, revealing defects and enhancing precision, especially in sectors like paintless dent repair and automotive body shops. Techniques such as LED lighting and reflective surfaces reduce shadows, while advanced optical aids access hard-to-reach areas. In manufacturing and assembly lines, adequate lighting improves safety, worker visibility, and product quality, leading to higher productivity, accuracy, cost savings, and better customer satisfaction, particularly in detailed-oriented tasks like hail damage repair.

Lighting and visibility are cornerstone elements in quality control (QC) inspection, ensuring defects are illuminated and precise assessments are made. In this article, we explore the multifaceted importance of these factors, delving into techniques that enhance defect detection, improve inspection accuracy, and promote safety and efficiency in QC processes. By understanding the role of lighting and visibility, organizations can optimize their quality control measures for enhanced product consistency and customer satisfaction.

- Illuminating Defects: The Role of Lighting in Quality Control

- Enhancing Visibility: Techniques for Accurate Inspection

- Safety and Efficiency: Benefits of Adequate Lighting in QC Processes

Illuminating Defects: The Role of Lighting in Quality Control

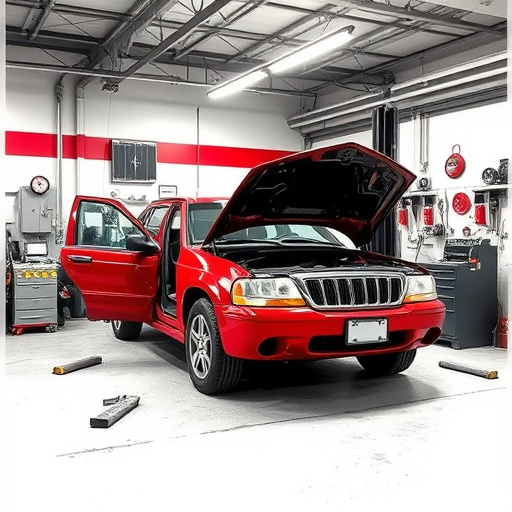

Proper lighting is an indispensable tool in quality control inspection, playing a pivotal role in revealing defects that might otherwise go unnoticed. In many industries, from automotive to manufacturing, the process of identifying and rectifying issues is heavily reliant on clear visibility. For instance, when it comes to car scratch repair or fender repair, accurate assessment demands well-lit conditions to ensure every imperfection, no matter how subtle, is captured and addressed during the inspection phase.

Effective lighting strategies can dramatically enhance the precision of quality control procedures, especially in specialized services like paintless dent repair. It enables inspectors to detect variations in surface texture, color consistency, and other visual cues that indicate subpar workmanship or materials. By illuminating these defects, businesses can maintain higher standards, ensuring customer satisfaction and upholding their reputation for excellence in their respective fields.

Enhancing Visibility: Techniques for Accurate Inspection

Enhancing visibility is a key aspect of successful quality control inspection, ensuring every detail is visible and nothing goes unnoticed. Techniques such as high-quality lighting systems, including LED lights, can significantly improve the clarity of inspection areas. This technology provides uniform illumination, reducing shadows that could mask defects or inconsistencies. In an automotive body shop or fleet repair service environment, where precision is paramount, this level of visibility becomes critical.

Inspectors can use reflective surfaces and proper positioning to maximize natural light, another effective technique. Additionally, advanced optical aids like magnifying glasses or specialized inspection tools with high-definition cameras enable a closer look at hard-to-reach or intricate areas, further enhancing the quality control process for vehicle body shop operations.

Safety and Efficiency: Benefits of Adequate Lighting in QC Processes

Adequate lighting is a fundamental aspect of any quality control (QC) inspection process. In the realm of manufacturing and assembly lines, well-lit work areas enhance both safety and efficiency. Workers can easily spot defects, imperfections, or inconsistencies in products when they have clear visibility, ensuring that only high-quality items reach the market. This is particularly crucial in industries where precision is key, such as automotive repair services, where even minor scratches or dents need to be addressed during the QC process to ensure customer satisfaction and safety on the road.

Moreover, proper lighting reduces eye strain and fatigue among inspectors, allowing them to maintain focus and attention to detail throughout the shift. This increased productivity and reduced error rates contribute to overall cost savings for businesses. In terms of specific applications like hail damage repair, where identifying and documenting every minute scratch or mark is essential, optimal lighting conditions enable detailed assessments, leading to more accurate repairs and better customer outcomes.

In conclusion, proper lighting and enhanced visibility are indispensable components of a successful quality control inspection process. By illuminating defects and ensuring clear, unobstructed views, these factors significantly improve accuracy, efficiency, and safety in manufacturing environments. Investing in strategic lighting solutions and adopting advanced visibility techniques directly contributes to the overall quality of products and can provide significant competitive advantages for businesses in the dynamic market of quality control inspection.