Quality control (QC) inspection is vital in vehicle collision repair, ensuring safety, excellence, and customer trust. It verifies repairs against standards, enhancing overall quality, saving resources, and rectifying issues early. For advocating QC in auto glass or bodywork, communicate its benefits—maintaining high standards and minimizing future problems—with specific details about industry standards and error-prone areas. To establish a robust QC process, set clear 'quality' standards through precise measurements, visual assessments, and systematic inspections at each repair stage. Regular training sessions and detailed inspection records of deviations further enhance consistency and promote continuous improvement.

Quality control (QC) inspection is an essential step in ensuring the reliability and durability of repair jobs. This article guides you through understanding the value of QC, advocating for it, and implementing best practices. By learning effective strategies, you can enhance job quality, reduce defects, and build customer satisfaction. Discover how to ensure every repair meets high standards, fostering trust and excellence in your work. Master the art of QC advocacy for successful and sustainable outcomes.

- Understanding Quality Control Inspection: Its Importance and Benefits

- Steps to Advocate Effectively for QC Inspection in Repair Jobs

- Best Practices for Ensuring a Comprehensive Quality Control Process

Understanding Quality Control Inspection: Its Importance and Benefits

Quality control inspection is a vital process that plays a crucial role in ensuring the excellence and safety of vehicle collision repair, particularly when it comes to fender repair or car body shop services. It involves a thorough examination of the work done during the repair process to verify if it meets the required standards and specifications. This meticulous review process benefits both customers and repair facilities. For customers, it guarantees that their vehicles are restored to pre-accident condition, ensuring their safety on the road. For repair shops, quality control inspection helps maintain high standards, which can enhance their reputation and foster customer trust.

By implementing rigorous quality control measures, car body shop professionals can identify any potential issues or deviations from the original plan, allowing for immediate corrections. This proactive approach not only improves the overall quality of repairs but also saves time and resources in the long run. Moreover, it adds value to the entire repair experience, ensuring that customers receive top-notch service and a vehicle that is as good as new.

Steps to Advocate Effectively for QC Inspection in Repair Jobs

To effectively advocate for a quality control (QC) inspection on your repair job, start by clearly communicating the benefits to both parties. Emphasize how a QC inspection ensures the work meets high standards and reduces potential errors or future issues with the auto glass repair or vehicle bodywork. This demonstrates your commitment to providing superior auto repair services and builds trust with clients.

Next, be prepared with specific details about the scope of work and any relevant industry standards. Highlight areas that are particularly prone to errors, such as intricate repairs or parts with a high failure rate. Presenting a well-structured case based on facts and best practices will make your argument more persuasive.

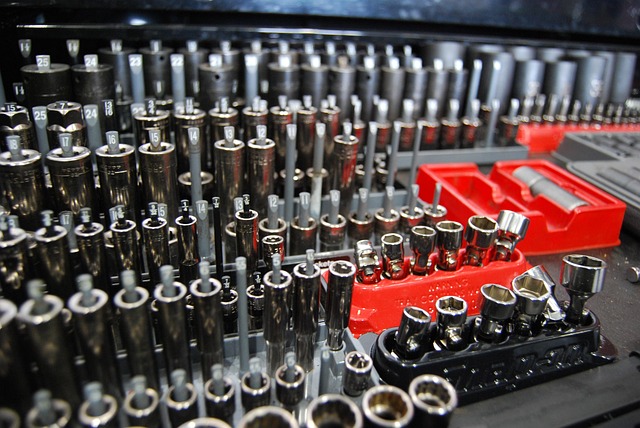

Best Practices for Ensuring a Comprehensive Quality Control Process

To ensure a comprehensive quality control process for your repair jobs, whether it’s an auto glass repair, auto collision repair, or vehicle dent repair, start by establishing clear standards and criteria. Define what constitutes ‘quality’ in each specific service, outlining precise measurements, specifications, and visual assessments. This standardization ensures consistency across all repair projects.

Implement a systematic inspection process where every step of the repair is meticulously evaluated. Encourage your team to ask questions, challenge assumptions, and double-check their work. Regular training sessions on quality control best practices can foster a culture of continuous improvement. Additionally, maintain detailed records of each inspection, documenting any deviations from standards and the corrective actions taken, for future reference and process enhancement.

Quality control (QC) inspection is an indispensable step in ensuring the excellence and longevity of repair jobs. By advocating for QC, you’re not just enhancing your work’s precision but also building trust with clients. The benefits are clear: it reduces errors, prevents costly rework, and guarantees customer satisfaction. Following the best practices outlined in this article will empower you to effectively promote QC inspection, ultimately elevating the standards of your repair services.