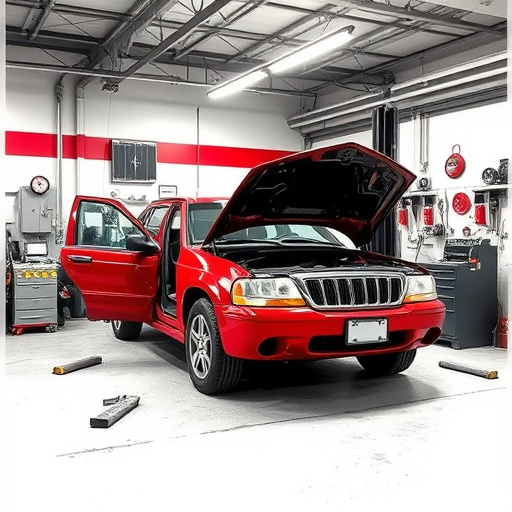

Quality control inspection ensures automotive manufacturing and repair meet high standards for paint, fit, and finish. Trained professionals evaluate color consistency, body panel alignment, and dent removal quality to maintain aesthetics and structural integrity. Robust QC procedures, including measurement and specialized tools, guarantee consistent standards in restoration and collision repair, with emphasis on visual appeal and durability.

Quality control (QC) inspection is a vital process ensuring paint, fit, and finish meet stringent standards. This comprehensive guide delves into the essentials of QC inspection basics, exploring critical considerations for paint, fit, and finish. We provide actionable strategies to implement effective QC procedures, empowering professionals to maintain high standards across industries. By understanding these key aspects, you’ll enhance efficiency, reduce defects, and deliver superior products.

- Understanding Quality Control Inspection Basics

- Paint, Fit, and Finish Standards: Key Considerations

- Implementing Effective QC Inspection Procedures

Understanding Quality Control Inspection Basics

Quality control inspection is a critical process that ensures the highest standards are met in automotive manufacturing and repair, particularly for paint, fit, and finish. It involves a systematic evaluation of vehicles or components to identify any deviations from the established specifications. This meticulous practice is essential across various industries, including autobody repairs and automotive restoration, where precision is paramount.

During a quality control inspection, trained professionals examine the paint job for consistency in color, texture, and application, ensuring it meets the desired finish. They check for proper alignment and fit of body panels, addressing any issues like misalignments or gaps that could impact the overall aesthetics and structural integrity of the vehicle. Moreover, this process also encompasses assessing the quality of dent removal, a common procedure in autobody repairs, guaranteeing that the repair is seamless and unnoticeable upon completion.

Paint, Fit, and Finish Standards: Key Considerations

Paint, Fit, and Finish standards are paramount in ensuring vehicle aesthetics and durability. During a quality control inspection, several key considerations come into play. For instance, color consistency across different parts is crucial, as is the evenness of paint application, avoiding runs or drips. The fit of components must be precise to prevent gaps or overlaps that can compromise structural integrity and overall finish.

Additionally, the finish should be smooth and free from defects like bubbles, cracks, or pinholes. This involves rigorous testing for scratch repair and restoration, especially in automotive repair services where car paint services are frequently utilized to fix damages. Maintaining these standards not only enhances the visual appeal of vehicles but also guarantees long-lasting performance, making them a vital aspect of any comprehensive quality control inspection process.

Implementing Effective QC Inspection Procedures

Implementing effective quality control (QC) inspection procedures is paramount for achieving consistent paint, fit, and finish standards in automotive restoration or collision repair projects. It’s not just about checking for visible defects; it involves a meticulous process that ensures every component meets pre-determined specifications. This includes meticulous measurement, careful visual examination, and, where necessary, the use of specialized tools to detect even subtle discrepancies.

For instance, in paintless dent repair (PDR), a skilled technician will employ techniques like light reflection and digital measuring tools to ensure paint thickness, color match, and surface smoothness adhere to strict standards. Similarly, in automotive collision repair, QC inspections should verify the proper alignment of panels, the quality of welds, and the flawless application of primer and finish coats. Regular training and standardization of these procedures across all workshops are key to maintaining a high level of craftsmanship.

Quality control (QC) inspection for paint, fit, and finish standards is a multifaceted process that ensures product excellence. By understanding basic QC principles, considering key factors like material specifications and environmental conditions, and implementing robust procedures, manufacturers can achieve consistent, high-quality outcomes. Effective QC inspection not only safeguards against defects but also enhances customer satisfaction and fosters market competitiveness, making it an indispensable practice in modern manufacturing.