Quality control inspection is a stringent process vital for automotive workshops, especially collision repair shops and car body restoration facilities. Skilled technicians meticulously evaluate welds, fasteners, and torque specifications to ensure structural integrity, safety, and aesthetic appeal. Strict adherence to fastener and torque specs prevents component loosening, maintains vehicle longevity, and safeguards against structural failures. Best practices include establishing clear protocols, standardizing procedures, regularly training inspectors, and integrating advanced technologies like digital measurement tools and automated inspection systems. These measures are crucial for maintaining high standards in various industries, enhancing accuracy, and identifying defects missed by the human eye.

“In the realm of manufacturing, ensuring structural integrity through meticulous quality control inspection is paramount. This article delves into the critical practices of evaluating welding, fasteners, and torque specs, offering a comprehensive guide for maintaining superior product standards. From understanding the fundamentals of quality control in welding to mastering fastener and torque specifications, readers will gain insights into best practices for effective inspections. Embrace these strategies to revolutionize your quality assurance processes.”

- Understanding Quality Control Inspection for Welding

- Fastener and Torque Specs: Ensuring Structural Integrity

- Best Practices for Effective Quality Control Inspections

Understanding Quality Control Inspection for Welding

Quality control inspection is a vital process in any automotive workshop, particularly in collision repair shops and car body restoration facilities. It involves a meticulous evaluation of welded joints, fasteners, and torque specifications to ensure that every vehicle leaves the shop meeting stringent safety and quality standards. This rigorous scrutiny is crucial for maintaining the structural integrity of cars, especially after repairs or modifications.

During a quality control inspection, skilled technicians examine welds for consistency, precision, and adherence to industry-defined parameters. They check fastener torque to guarantee secure connections, preventing potential failures during driving. In the context of car bodywork, this process ensures that panels fit perfectly, preserving the aesthetic appeal and overall safety of the vehicle. Effective quality control not only enhances the reputation of a collision repair shop but also plays a significant role in ensuring customer satisfaction and road safety.

Fastener and Torque Specs: Ensuring Structural Integrity

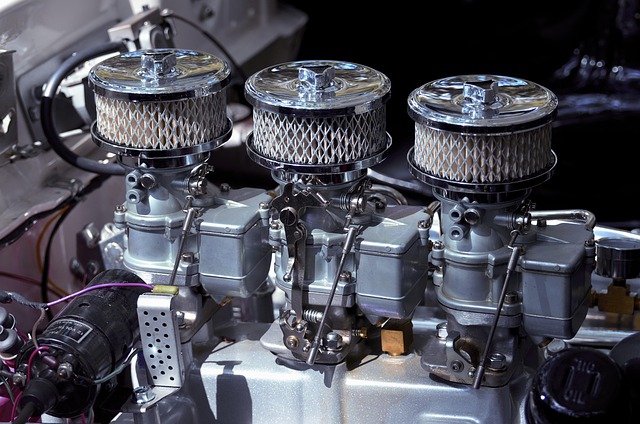

Fastener and torque specs play a pivotal role in ensuring the structural integrity of any welded assembly. During a quality control inspection, meticulous attention is given to these critical dimensions to verify that each fastener is installed according to the manufacturer’s specifications. This includes checking torques to ensure secure connections and prevent loosening over time, which could compromise the safety and reliability of the entire structure.

In industries such as auto collision repair or car paint services, where precision matters, adhering to strict torque specs is paramount. Skilled inspectors use specialized tools to measure torque values, ensuring that bolts and nuts are tightened with the correct force, neither too tight nor too loose. This meticulous process not only safeguards against structural failures but also helps in maintaining the longevity of vehicles undergoing auto dent repair or car paint services, ensuring a sturdy foundation for any subsequent repairs or modifications.

Best Practices for Effective Quality Control Inspections

To ensure effective quality control inspections for welding, fasteners, and torque specs, several best practices should be followed. First, establishing clear and detailed inspection protocols is essential. These protocols should cover every aspect of the welding process, including pre-welding preparation, the actual welding itself, and post-welding checks. Standardized procedures guarantee consistency in the inspection process, reducing human error and enhancing accuracy. Regular training sessions for inspectors are also vital to maintaining high standards. Inspectors should be well-versed in industry best practices, equipment operation, and relevant safety protocols.

Additionally, integrating advanced technologies can significantly enhance quality control. Utilizing digital measurement tools, such as calipers and laser scanners, allows for precise data capture and comparison against established specifications. Automated inspection systems and computer-aided detection software can also identify defects that might be missed by the human eye, especially in complex or intricate components. Much like how car paint services and auto glass repair rely on technology for precision, effective quality control inspections benefit from these innovations to maintain high standards across various industries, including collision repair.

Quality control inspection plays a pivotal role in ensuring the structural integrity of welded components. By meticulously adhering to fastener and torque specs, industries can prevent costly failures and maintain safety standards. Implementing best practices for quality control inspections fosters efficiency, reduces errors, and ultimately ensures the reliability of products and structures across various sectors.