A meticulous quality control inspection (QCI) in auto repair combines skilled technicians' visual exams and advanced diagnostic tools to ensure vehicle excellence. Balancing optimism and realism in QCI timelines guarantees detailed attention, client satisfaction, and superior results, especially in complex cases, with transparent communication at each critical milestone.

Quality control (QC) inspections are a vital step in ensuring product excellence. This article explores the timeline expectations for completing QC, breaking down the process into manageable phases. We’ll guide you through setting realistic timeframes, identifying key milestones, and understanding their influence on the overall timeline. By understanding these elements, businesses can effectively manage QC processes, meet production deadlines, and deliver high-quality products consistently.

- Understanding Quality Control Inspection Phases

- Setting Realistic Completion Timeframes

- Key Milestones and Their Impact on Timeline

Understanding Quality Control Inspection Phases

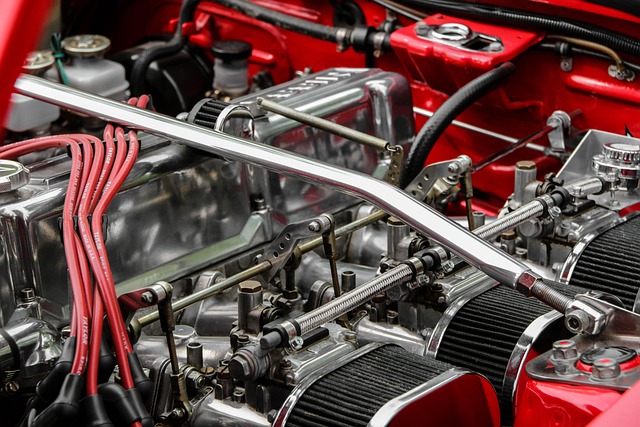

A quality control inspection is a meticulous process that ensures every aspect of a product or service meets the highest standards. When applied to vehicle repair services, this process involves several key phases, each playing a crucial role in maintaining excellence. The initial phase focuses on visual and manual examinations, where skilled technicians inspect the vehicle for any visible defects, misalignments, or signs of previous repairs. This step is critical as it provides an overview of the car’s condition and guides subsequent inspections.

Following this, advanced diagnostic tools are employed to delve deeper into the vehicle’s systems. In a top-tier auto repair shop or collision center, modern technology allows for precise assessments, identifying even subtle issues that may impact performance or safety. This phase ensures that every component—from engines and transmissions to brakes and lighting systems—functions optimally. By combining human expertise with technological advancements, these facilities deliver superior quality control, guaranteeing customer satisfaction and roadworthiness in every vehicle leaving their premises.

Setting Realistic Completion Timeframes

When setting expectations for a quality control inspection timeline, it’s crucial to strike a balance between optimism and realism. In the realm of automotive repair, vehicle restoration, or car paint services, each project is unique with varying complexities that can impact turnaround time. While a swift turnaround may be desirable, overly ambitious deadlines can lead to subpar work as inspectors rush through essential checks. On the other hand, allowing too much leeway might cause delays in the overall production line, impacting client satisfaction and operational efficiency.

To navigate this fine line, consider breaking down the inspection process into distinct stages, each with its own reasonable timeframe. For instance, initial visual inspections could be completed within a day or two, followed by more detailed, time-consuming tasks like checking paint consistency in car paint services or assessing intricate mechanical components in automotive repair. Realistic completion timeframes not only manage client expectations but also ensure that every aspect of the quality control process receives adequate attention, ultimately delivering superior results for vehicle restoration projects.

Key Milestones and Their Impact on Timeline

The timeline for a quality control inspection (QCI) is meticulously planned, with key milestones acting as guiding beacons to ensure a comprehensive and timely process. These milestones are crucial checkpoints that dictate the overall duration and success of the QCI, especially in complex vehicle collision repair scenarios. For instance, the initial phase involves meticulous dent removal and car paint repair, which sets the stage for subsequent intricate work. Each stage builds upon the last, demanding precision and adherence to strict quality standards.

As the process advances, inspections at various stages become increasingly detailed. This includes rigorous assessments of panel gaps, paint consistency, and overall aesthetic integrity following repairs like dent removal. These milestones not only ensure that every vehicle meets the highest standards but also play a pivotal role in managing expectations among stakeholders. Effective communication regarding these key checkpoints keeps everyone informed, fostering transparency throughout the quality control process.

In conclusion, managing the timeline for a quality control inspection involves a strategic approach. By understanding the phases, setting realistic expectations, and identifying key milestones, organizations can ensure efficient operations without compromising quality. Effective navigation of these checkpoints is vital for successful project completion, emphasizing the importance of a well-planned and executed quality control inspection process.