Post-repair road tests and thorough quality control inspections are vital for maintaining industry standards and customer satisfaction in automotive repairs. These tests simulate real-world conditions to verify structural integrity, performance, and safety of vehicles post-repair, ensuring optimal vehicle operation and high-quality craftsmanship. Key aspects include functional testing of systems, documentation verification, and assessing aesthetics for both performance and appearance guarantees.

Post-repair road testing is an indispensable step in the quality control (QC) process, ensuring vehicles meet safety and performance standards after repairs. This comprehensive guide explores the significance of these tests, delving into their key components and best practices. By implementing effective post-repair evaluation strategies, automotive facilities can enhance customer satisfaction, maintain reputation, and uphold the highest QC standards.

- Understanding Post-Repair Road Tests

- Key Components of Quality Control Inspection

- Best Practices for Effective Post-Repair Evaluation

Understanding Post-Repair Road Tests

Post-repair road tests are a crucial component of any comprehensive quality control inspection process. These tests serve as a final assessment to ensure that vehicle repairs meet industry standards and customer expectations. After a bumper repair, auto glass replacement, or hail damage repair, it’s essential to verify the structural integrity and overall performance of the vehicle on the road.

During these tests, trained technicians drive the vehicle at various speeds and in different conditions to simulate real-world scenarios. They assess factors like handling, braking, tire pressure, and alignment. This meticulous process helps identify any lingering issues that might have been overlooked during the repair work, ensuring that the vehicle is safe to operate and maintains optimal performance. It’s a critical step in maintaining high-quality standards within the automotive industry.

Key Components of Quality Control Inspection

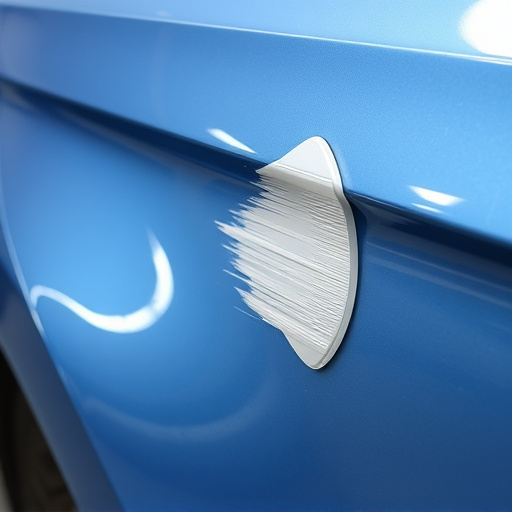

A comprehensive quality control inspection goes beyond surface-level aesthetics to ensure that every vehicle leaving a body shop is in prime condition and safe for the road. This meticulous process involves several critical components, each playing a vital role in upholding the highest standards of craftsmanship. The initial step centers around meticulously evaluating the repair work performed on collision damage repair, scrutinizing both structural integrity and precision of repairs. Every detail, from panel gaps to alignment, is carefully assessed to guarantee that the vehicle meets pre-accident specifications.

Additionally, quality control inspection includes functional testing of all repaired systems, such as brakes, lighting, and safety mechanisms. These checks ensure that each component not only appears mended but also operates optimally, enhancing the overall roadworthiness of the vehicle. Moreover, a thorough review of documentation and records is conducted to verify compliance with industry standards and regulations, ensuring transparency and accountability in body shop services.

Best Practices for Effective Post-Repair Evaluation

When conducting a post-repair road test as part of a quality control inspection, best practices involve evaluating the vehicle’s performance under various driving conditions. This includes acceleration, braking, handling, and comfort levels. It’s crucial to simulate real-world scenarios to ensure the car handles seamlessly on the road after auto body services or vehicle restoration. Check for any unusual noises, vibrations, or handling issues that may indicate unresolved problems from the repair process, especially in car dent repair cases.

During this test, pay close attention to the vehicle’s aesthetics as well. Inspect the paint job, panel gaps, and overall finish to ensure they meet the expected standards. This step is vital for maintaining customer satisfaction, as it guarantees that not only does the vehicle drive excellently but also looks impeccable after completion of services like car dent repair or comprehensive vehicle restoration projects. Remember, a thorough quality control inspection should capture both the visible and functional aspects of auto body services.

A comprehensive quality control inspection, including a post-repair road test, is essential for ensuring vehicle reliability and customer satisfaction. By incorporating these tests as a standard procedure, repair shops can identify any residual issues and make necessary adjustments, thereby upholding the highest standards of workmanship. This meticulous approach to quality control not only guarantees superior results but also fosters trust among clients, positioning your business as a leader in the industry through its commitment to excellence.