Quality control inspections are crucial in automotive manufacturing and repair, ensuring products meet high standards. Skilled inspectors assess structural integrity, paint quality, and cosmetic appearance, identifying defects that would otherwise reach customers. This process enhances customer satisfaction and maintains auto body shops' reputations through meticulous examination using specialized tools and technologies, addressing common issues like misalignments and non-compliance with standards to prevent costly rework in a competitive market.

In the retail landscape, ensuring product quality is paramount to customer satisfaction and brand reputation. Final Quality Control (FQCI) inspections play a crucial role in identifying defects before products reach consumers. This article delves into the strategies that shops employ to handle issues uncovered during FQCI, emphasizing rapid response protocols, effective communication, comprehensive documentation, and preventive measures for continuous improvement. Understanding common inspection findings is key to implementing robust quality assurance practices.

Understanding Final Quality Control Inspection

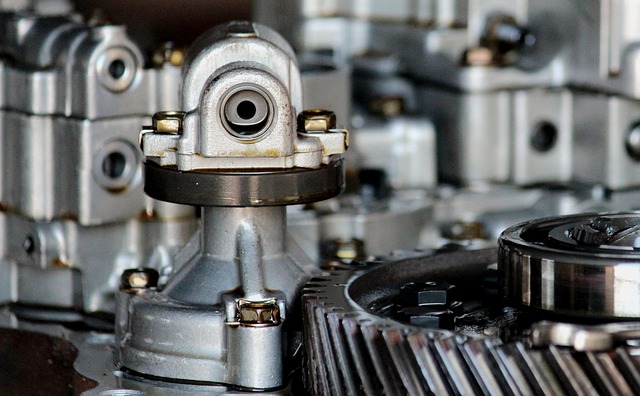

A final quality control inspection is a crucial step in the manufacturing and production process, particularly in industries like automotive, where precision and detail are paramount. It involves a thorough examination of products or vehicles to identify any defects, discrepancies, or damage that may have gone unnoticed during previous stages. In the context of an auto body shop, this inspection is essential as it ensures the final product—be it a repaired vehicle or freshly painted auto—meets the required standards and specifications.

During this process, skilled inspectors meticulously assess various aspects, including structural integrity, paint quality (in auto painting processes), and overall cosmetic appearance. Any issues found, such as a minor dent or an uneven coat of paint (potentially indicating a fender bender), are documented and used as a baseline for improvement. This inspection acts as a filter, allowing shops to rectify problems before delivering the finished product to customers, thereby enhancing customer satisfaction and maintaining their reputation in a highly competitive market.

– Definition and purpose

Quality control inspection is a meticulous process designed to identify defects or issues in products or services before they reach customers. In the context of vehicle collision repair and automotive repair services, it’s a critical step ensuring that every car or part meets the highest standards of safety and functionality. This inspection involves thorough examination, often using specialized tools, to detect any discrepancies from the expected outcomes.

The primary purpose is to catch potential problems early in the production or restoration process, whether it’s a minor dent during a vehicle collision repair or a faulty component in automotive repair services. By implementing rigorous quality control inspections, shops can prevent costly mistakes, enhance customer satisfaction, and maintain their reputation for delivering top-tier vehicle restoration services.

– Common issues identified

During a final quality control inspection, several common issues are often identified across various products and services, including those from car repair shops and auto body repairs facilities. These may include misalignments in manufacturing tolerances, cosmetic defects like scratches or dents, and non-compliance with industry standards or customer specifications. For instance, in the auto body repairs sector, misaligned panels, improperly applied paints, and inconsistent sanding are frequent concerns. In a car repair shop environment, common issues can range from faulty assembly of mechanical parts to incorrect installations of electrical components.

Effective quality control processes in both auto body repairs and car repair shops involve meticulous checks at each stage of production or service delivery. This includes the use of specialized tools and equipment for precise measurements, visual inspections under high-resolution cameras, and even advanced technologies like 3D scanning for detailed analysis. By addressing these issues early, shops can minimize the need for costly rework, enhance customer satisfaction, and maintain their reputation in a competitive market driven by stringent quality control inspection standards.

Shops employ robust quality control inspection processes to ensure product excellence. When issues are identified, immediate action is taken, involving either repair, replacement, or, in severe cases, product recall. Effective handling of these issues not only maintains customer satisfaction but also strengthens the shop’s reputation and fosters trust in their products, ultimately enhancing their brand image. Regular quality control inspections remain a cornerstone of any successful retail operation, ensuring that every item leaving the premises meets the highest standards.