Quality control (QC) inspection is vital in collision repair, ensuring precision and craftsmanship. Skilled inspectors meticulously assess vehicles, from panel alignment to mechanical functionality, preventing errors and inconsistencies. Regular QC inspections are crucial for complex repairs, saving time, resources, and guaranteeing customer satisfaction by meeting high standards and industry benchmarks. Reputable shops prioritizing QC build client trust, delivering exceptional, reliable collision repair services.

In the intricate process of collision repair, Quality Control (QC) inspection stands as a cornerstone of excellence. This meticulous practice ensures that every vehicle undergoes rigorous scrutiny before leaving the workshop. By implementing regular QC checks, repair facilities can prevent costly mistakes, maintain precision, and ultimately satisfy customers. This article delves into the significance of QC, exploring its pivotal role in accuracy, error prevention, and customer satisfaction, thereby underscoring why it’s an indispensable aspect of collision repair.

- Ensuring Accuracy: The Role of Quality Control

- Preventing Mistakes: Benefits of Regular Inspection

- Customer Satisfaction: Meeting Standards and Expectations

Ensuring Accuracy: The Role of Quality Control

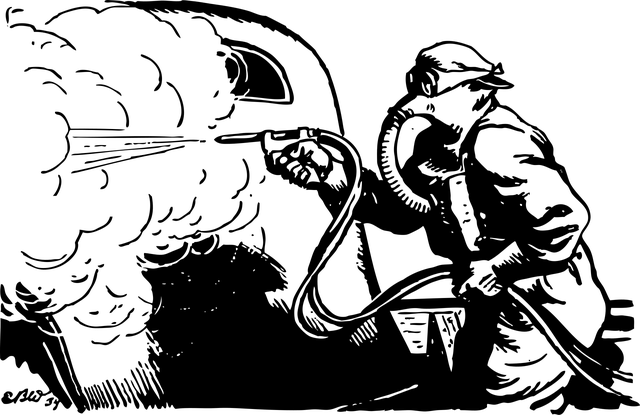

Quality control (QC) inspection plays a pivotal role in ensuring accuracy and excellence during collision repair processes. In the intricate world of car restoration, where every detail matters, QC acts as the guardian against potential errors and inconsistencies. Skilled inspectors meticulously assess each repaired vehicle, scrutinizing every panel, paint job, and mechanical component to verify that they meet the highest standards. This rigorous process is vital in maintaining customer satisfaction and ensuring the safety of drivers on the road.

Accurate QC inspections go beyond simply identifying visible defects; it involves a comprehensive understanding of auto repair services and collision damage repair methodologies. Inspectors must possess a deep knowledge of various car makes and models, as well as the latest repair techniques, to make informed judgments. By implementing robust QC practices, collision repair shops can deliver top-notch results, foster trust among customers, and maintain their reputation in a highly competitive market.

Preventing Mistakes: Benefits of Regular Inspection

Regular quality control inspection plays a pivotal role in preventing mistakes during collision repair. It acts as a vigilant guardian, ensuring that every step of the repair process adheres to the highest standards. By conducting meticulous checks, technicians can identify and rectify issues early on, avoiding costly rework later. This proactive approach is particularly beneficial for intricate tasks such as car scratch repair, vehicle paint repair, and auto glass repair, where even minor oversights can compromise the final outcome.

Preventing mistakes not only saves time and resources but also guarantees customer satisfaction. A thorough quality control inspection ensures that every detail, from panel alignment to paint consistency, meets the client’s expectations. By fostering a culture of precision and excellence, these inspections contribute to building a solid reputation for collision repair services, fostering trust among clients who rely on their vehicles’ restoration to pristine condition.

Customer Satisfaction: Meeting Standards and Expectations

In the realm of collision repair, customer satisfaction is paramount. Quality control inspection plays a pivotal role in meeting and exceeding standards and expectations. When a car repair shop undertakes a fender repair or auto glass replacement, it’s not just about fixing the physical damage; it’s about restoring peace of mind for the customer. A meticulous quality control process ensures that every component is repaired or replaced to original specifications, guaranteeing not only the structural integrity of the vehicle but also the safety and satisfaction of its owner.

This critical step in the repair process serves as a quality assurance mechanism, verifying that each repair adheres to industry standards and the shop’s own high benchmarks. By implementing robust quality control inspection protocols, reputable car repair shops can foster trust with their clients, ensuring they walk away feeling confident that their vehicle is in top condition. This positive customer experience is a hallmark of a professional, reliable, and customer-centric collision repair service.

Quality control inspection plays a pivotal role in collision repair, ensuring accuracy, preventing costly mistakes, and boosting customer satisfaction. By implementing regular checks, repair shops maintain high standards, meet client expectations, and safeguard their reputation. This meticulous process is a game-changer, transforming potential errors into opportunities for excellence, thus fostering trust among those who rely on these services.