Mastering quality control (QC) inspections through advanced tools, meticulous techniques, and comprehensive documentation is vital for exceptional vehicle repair outcomes in specialized sectors like hail damage repair and body restoration. Structured QC processes ensure consistency, maintain customer satisfaction, and enhance auto body shops' reputations by adhering to industry standards and manufacturer guidelines. Transparent communication and clear documentation guidelines facilitate informed decision-making, trend identification, and overall quality enhancement in dynamic industry standards.

In the realm of manufacturing and production, quality control (QC) inspection processes are paramount. Effective documentation plays a crucial role in ensuring these processes run smoothly and efficiently. This article delves into the intricate world of quality control inspections, highlighting the significance of comprehensive documentation. We explore how detailed records impact decision-making, streamline workflows, and ultimately enhance product quality. Furthermore, it offers best practices for creating efficient document systems, providing insights for professionals to optimize their QC strategies.

- Understanding Quality Control Inspection Processes

- The Impact of Comprehensive Documentation

- Best Practices for Effective Documentation in QC

Understanding Quality Control Inspection Processes

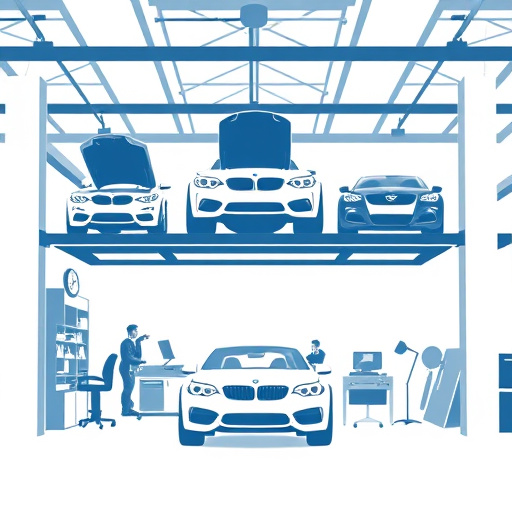

Understanding quality control inspection processes is paramount in ensuring optimal vehicle repair outcomes, especially in specialized areas like hail damage repair and vehicle body repair. These inspections serve as a critical step in the vehicle restoration journey, focusing on identifying any imperfections or discrepancies after repairs, such as paintless dent repair. Skilled inspectors meticulously assess every aspect of the repair work, from structural integrity to paint consistency, using advanced tools and techniques.

The primary goal is to verify that the repair process adheres strictly to industry standards and manufacturer specifications. By implementing thorough quality control inspections, auto body shops can guarantee customer satisfaction and maintain their reputation for excellence in services like hail damage repair or paintless dent repair. This meticulous approach not only ensures the safety of vehicles but also fosters trust between repair facilities and their clients.

The Impact of Comprehensive Documentation

Comprehensive documentation plays a pivotal role in enhancing the efficiency and accuracy of quality control inspection processes in industries such as auto body repairs, particularly within vehicle body repair shops and auto collision centers. Detailed records ensure that every step of the inspection process is meticulously recorded, providing a clear audit trail. This is essential for maintaining consistency and enabling easy identification of any deviations from set standards.

By documenting each phase of an auto body repair or collision center’s operations, inspectors can quickly compare actual results against established guidelines. This facilitates faster decision-making during quality control, ensuring that only vehicles meeting the required specifications are cleared for customer pickup. Effective documentation also simplifies issue tracking and troubleshooting, allowing for proactive measures to prevent future defects in vehicle body repair procedures.

Best Practices for Effective Documentation in QC

Effective documentation is a cornerstone of successful quality control (QC) inspection processes. To ensure accuracy and consistency, it’s crucial to establish clear guidelines for record-keeping throughout each stage of the inspection. Standardized forms or digital templates should be utilized to capture detailed information about the car paint repair or collision repair services performed, including dates, methodologies used, materials applied, and specific outcomes. This structured approach facilitates easy retrieval and analysis of historical data, enabling QC teams to identify trends, pinpoint areas for improvement, and make informed decisions to enhance overall quality.

Regular reviews and updates of documentation practices are essential in the dynamic world of car paint services and collision repair services. As new techniques and standards emerge, ensuring that documentation reflects these changes is vital to maintaining high-quality outcomes. Moreover, clear communication channels among team members and with clients foster transparency and accountability, aligning with best practices for effective QC documentation.

Documentation plays a vital role in enhancing the effectiveness and efficiency of quality control (QC) inspection processes. By meticulously recording every step, from inspection methods to findings and corrective actions, organizations can ensure consistency, facilitate knowledge sharing, and improve overall product or service quality. Implementing best practices for documentation, such as standardized templates, clear data organization, and digital record-keeping, allows for seamless navigation through the complex landscape of QC, ultimately driving operational excellence in today’s competitive market. This structured approach to documentation is a game-changer, enabling businesses to navigate the intricate process of quality control with precision and agility.