A quality control inspection is a rigorous, multi-faceted process in automotive collision repair that ensures exceptional standards and customer satisfaction. It involves detailed visual examinations, specialized tool assessments for alignment, functional tests, and scrutiny of materials and technician techniques to verify repairs meet manufacturer specifications, ensuring safety, reliability, and aesthetic restoration to pre-accident condition.

A collision repair quality control (QC) inspection is a meticulous process ensuring vehicles return to safe, road-ready condition. This in-depth review goes beyond visual appearances, assessing structural integrity, paint accuracy, and adherence to industry standards. Understanding the purpose of QC and what happens during an inspection equips car owners with knowledge, empowering them to make informed decisions post-repair. From panel alignment to finish quality, this guide breaks down key elements for a comprehensive assessment.

- Understanding the Purpose of Quality Control

- What Happens During an Inspection Process?

- Key Elements of a Comprehensive Assessment

Understanding the Purpose of Quality Control

A quality control (QC) inspection is a critical step in ensuring that vehicle collision repair meets the highest standards. Beyond simply checking for visible damage after a fender bender or more severe accident, QC involves a thorough examination of various components and systems. It verifies that the paintless dent repair techniques used are effective, preserving the car’s original finish and aesthetic appeal.

The primary purpose of a quality control inspection is to identify any defects, discrepancies, or areas that don’t align with established repair protocols. This includes assessing the accuracy of measurements, the proper application and blending of paint, alignment precision, and functionality of all systems after repair. By implementing rigorous QC procedures, automotive technicians can guarantee customer satisfaction and ensure the safety and reliability of every vehicle collision repair job.

What Happens During an Inspection Process?

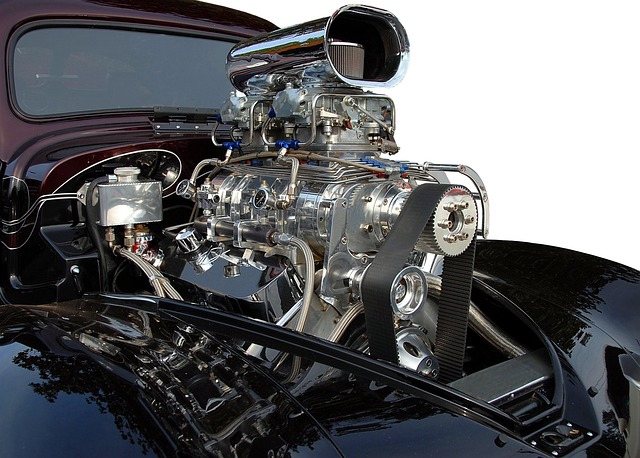

During a quality control inspection at a collision center, a trained technician meticulously evaluates every aspect of the repair work performed on a vehicle. This process involves a detailed visual examination, often aided by specialized tools to assess alignment and structural integrity. The inspector checks for any signs of improper repairs, ensuring that all parts are correctly fitted and aligned according to manufacturer standards. They carefully inspect areas like panel gaps, paint finishes, and the overall straightness of the vehicle body, pinpointing even the smallest imperfections.

In addition to physical assessments, a quality control inspection often includes functional tests. This may involve starting the vehicle’s engine, checking the operation of lights and signals, and verifying that all mechanical systems function as intended after the auto body repair. The goal is to ensure not just the visual aesthetics but also the overall safety and reliability of the vehicle, giving owners peace of mind that their collision center has provided high-quality service.

Key Elements of a Comprehensive Assessment

A comprehensive quality control inspection goes beyond a surface-level assessment. It involves meticulous examination of various key elements to ensure every aspect of the collision damage repair (CDR) process meets the highest standards. The first step is evaluating the car bodywork services for precision and accuracy in repairs, including straightening panels, aligning frames, and ensuring proper paint job. This includes checking for any gaps or misalignments that could indicate subpar work.

Additionally, a thorough inspection delves into the quality of materials used in the car body restoration. It scrutinizes the compatibility and condition of parts, verifying their adherence to manufacturer specifications. The expertise of technicians is also assessed through an analysis of their repair techniques, ensuring they follow best practices and industry standards. This holistic approach guarantees that the final product not only looks good but also stands the test of time, restoring the vehicle to its pre-accident condition or even enhancing its aesthetic appeal.

A thorough quality control (QC) inspection is essential for ensuring that collision repair work meets high standards. By understanding the key elements and processes involved, you can expect accurate assessments, confident repairs, and exceptional vehicle restoration. A QC inspection is a critical step in upholding reputation, customer satisfaction, and safety on the road.