A quality control (QC) inspection is a critical step in collision repair, ensuring vehicles meet pre-accident standards. Trained professionals use advanced tools to meticulously evaluate alignment, paint consistency, and structural integrity, addressing any deviations from original specifications. This process is especially vital for classic car restoration and luxury vehicle repairs, guaranteeing safety, reliability, and aesthetic preservation over time. Myth-busting shows that QC involves thorough examination, not just visual checks, and is essential for customer satisfaction across all manufacturers.

Collision repair quality control (QC) inspection is a critical process ensuring vehicles meet high standards after accidents. However, myths persist that cloud consumer understanding. This article demystifies common misconceptions and delves into the essential processes of QC inspections. We explore best practices guaranteeing top-notch repairs, empowering consumers to make informed decisions and fostering trust in collision centers’ capabilities.

- Understanding Quality Control Inspection Processes

- Debunking Common Collision Repair Myths

- Ensuring Top-Notch Results Through QC Practices

Understanding Quality Control Inspection Processes

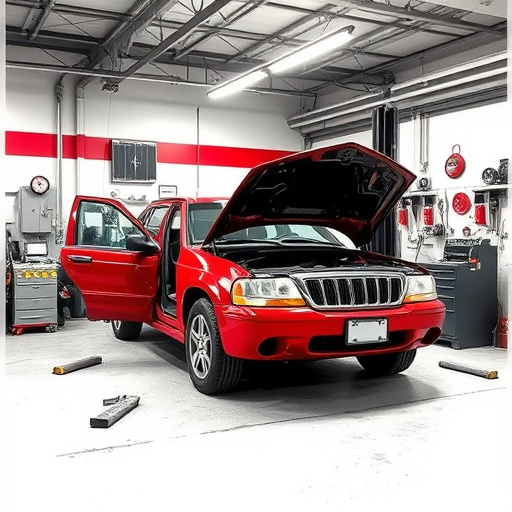

A quality control (QC) inspection is a vital step in the collision repair process, ensuring that vehicles are restored to their pre-accident condition accurately and safely. It involves a meticulous evaluation by trained professionals who scrutinize every detail of the repair work. This includes checking for proper alignment, paint consistency, and structural integrity. The primary goal is to identify any deviations from the original specifications and rectify them before the car leaves the workshop.

In the context of collision repair, QC processes are designed to be comprehensive, addressing not just visible repairs like dent removal or car scratch repair but also underlying structural components. For classic car restoration projects, this level of detail is even more critical as it requires a deep understanding of historical vehicle manufacturing standards and techniques. A thorough QC inspection ensures that every repair, no matter how small, meets the highest standards, preserving both functionality and aesthetics for years to come.

Debunking Common Collision Repair Myths

Many misconceptions surround collision repair quality control inspection, leading many vehicle owners to doubt the integrity of the process and the final product. One common myth is that a quick visual check is sufficient for ensuring top-notch repairs. However, a comprehensive quality control (QC) inspection involves meticulous examination by trained professionals using advanced tools and techniques, guaranteeing that every detail is accounted for—from alignment and paint consistency in auto painting services to structural integrity across all vehicle repair services.

Another debunked myth is that only major manufacturers like Mercedes-Benz collision repair centers employ rigorous QC standards. In reality, top-tier practices are industry-wide, as quality control inspection is a vital process that ensures customer satisfaction and safety. It’s not just about aesthetics; proper repairs prevent future issues, ensuring your vehicle remains safe and reliable on the road.

Ensuring Top-Notch Results Through QC Practices

Collision repair facilities play a crucial role in ensuring that vehicles return to their pre-accident condition. To achieve top-notch results, implementing robust quality control (QC) practices is essential. A thorough QC inspection process involves meticulously evaluating every aspect of the repair work, from panel alignment and paint job to functionality of all systems and components, including auto glass repair. This meticulous approach guarantees that no detail goes unnoticed, ensuring customer satisfaction and safety on the road.

Regular QC inspections also serve as a quality control measure for luxury vehicle repairs, where precision and craftsmanship are paramount. By adhering to strict standards during these inspections, repair facilities can maintain high-quality outcomes, even for intricate components like those in high-end vehicles. This not only preserves the aesthetic appeal but also ensures the reliable performance of the vehicle, including proper functionality of any replacement auto glass.

Collision repair quality control (QC) inspection is a vital process ensuring vehicles return to the road safely and effectively. By understanding the processes, debunking myths, and adopting top-notch QC practices, shops can maintain high standards, satisfy customers, and foster trust in their work. Implement these strategies to elevate your collision repair game and deliver exceptional results every time.